Based on the Airfreight Conference https://www.airfreightconference.com/ jointly organized between Europhia Consulting and ProMedia Dutch Logistics media group, some key points emerged from the speaker presentations and discussions:

- Various speakers confirmed that restrictions in airfreight capacity supply due to the ongoing COVID-19 crisis which have impacted the airline industry will likely drive up airfreight pricing in 2021. The vaccines come on top of already tight aircargo capacity and will lead to airfreight price increases.

- Due to the enormous capacity requirement for airfreight to support global vaccine distribution there is room for a global procurement platform to better co-ordinate and align global airfreight capacity and pricing between the supply and demand of aircargo.

- Importance for the industry to work closer together across the full end to end distribution chain from factory to final vaccination points. Improved involvement of supply chain expertise to support vaccine manufacturers and government bodies to design safe, agile and efficient distribution models in crucial to speed up the process of vaccine distribution the coming months. We are already experiencing delays in distribution due to lack of end to end planning.

Example: Pfizer vaccine will likely be EMA approved for emergency use within the EU on December 21st. However a number of EU governments such as the Dutch government are saying their distribution plans are not ready and they will not be ready to start their immunisation program until January 8th, 2021. That’s almost 3 weeks later than the likely approval date. Industry logistics experts are surprised that these delays are required as the governments have had months of time to prepare the timely introduction of immunisation through their national COVID-19 taskforces.

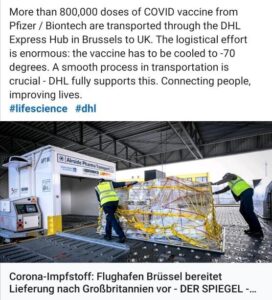

- Pfizer is falling behind in its own production and distribution forecasts given several weeks ago. Pfizer mentioned earlier 100 million vaccines would be distributed before the end of 2020. This forecast has fallen back to only 30 Million vaccines. The company is siting some production and distribution delays but not explaining what is causing these delays. It is already clear that the company has designed only one packaging solution using Softboxes with dry-ice to distribute its -70 degrees Celsius vaccines around the world. The dry-ice limitation in airfreight means that any aircraft is very limited in being able to carry Pfizer’s minus 70 vaccines. IATA and the FAA are currently reviewing dry-ice guidelines together with aircraft manufacturers Boeing and Airbus. Industry experts such as Europhia Consulting suggest that Pfizer also explore alternative packaging types available to increase its ability to distribute vaccines faster.

- Disruptive next generation packaging solutions. The pharmaceutical industry and airlines are in dire need of next generation active and passive packaging concepts to better cool pharmaceuticals including vaccines and reduce the risk of temperature excursions. Current active containers use heavy batteries which can’t be recharged during flights and don’t last long. Next generation Phase Changing Material PCM containers from companies such as Skycell en Vaqtec provide much better solutions, allow far longer cooling times, are much lighter and are more cost effective.

- The conference highlighted that end to end global tracking and product visibility of vaccines from factory to final points of dispensing using data remains a complex issue the industry still struggles with. One of the key reasons is that many different logistics and transport companies often play a partial role in transport and storage from first mile, through airports, on airlines and final mile distribution. Better orchestration of the entire end to end distribution supply chain remains a big challenge.

- Final mile distribution. The conference also highlighted that getting the vaccines at destination country to final points of use in hospitals, clinics and other immunisation points remains a critical gap in current distribution planning. Governments play a key role here and we believe they should reach out earlier to the logistics industry for support in sorting this out asap. Countries such as the Netherlands acknowledge they are still working on how best to set up final mile models which will likely delay first vaccine distribution with some weeks. Many emerging countries have not even started this planning process which could lead not just to problems in the timely availability of vaccines at the various immunisation points but also to problems in having too many vaccines which can’t be used without the required cool chain storage facilities which could lead to vaccines having to be destroyed. Timely preparation of final mile distribution planning is therefore critical.