Automation / robots take over the warehouse

Alain Kaddoum, General Manager, Swisslog Middle East speaks to Munawar Shariff and shares lots of insights into the current trends in the materials handling industry. Automation, he says, is not as expensive as is the general assumption in the market. Though many businesses understand that automation is the answer, not many invest in it. Reports show that a lot of companies are still afraid of using latest technologies in their business operations as they assume they are too expensive. Agile and future-oriented software is the critical key for companies to adapt to market changes today and in the future and keep their warehouse operations optimised at all times.

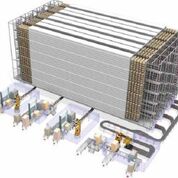

Many businesses seek an effective automated storage and retrieval system. Limited space, an awkward warehouse building, increasing inventory or turnover in unusual shapes or sizes can all make it difficult to find the right solution. The future for intralogistics isn’t in a single technology like robotics, or sensors, or even Big Data, but rather how these elements can be tied together. Flexible robotics and data-driven solutions is the direction we see.

As per current market conditions, a lot of businesses are experiencing changing consumer habits, increased operating expenses and other challenges. Though many businesses understand that automation is the answer, not many invest in it. Reports show that a lot of companies are still afraid of using latest technologies in their business operations as they assume they are too expensive. “I’d say this is one of the biggest challenge in this market. Businesses that are not going to implement any changes to the way they operate risk being left behind and the cost of inaction in this case can easily exceed the price of a modernisation project,” says Alain Kaddoum, General Manager, Swisslog Middle East.

Today, warehouses can be better equipped in numerous ways: agile and future-oriented software is the critical key for companies to adapt to market changes today and in the future and keep their warehouse operations optimised at all times. Businesses require a software solution that enables companies to optimise not only warehouse performance, but also their entire value chain. Many businesses seek an effective automated storage and retrieval system. Limited space, an awkward warehouse building, increasing inventory or turnover in unusual shapes or sizes can all make it difficult to find the right solution. Not only that, automated storage solutions need to be scalable while maximising space and performance. Staying flexible enough to respond to changing market requirements is also essential, as when new products launch, demand increases and regulations change. Picking and palletising is another critical requirement for warehouses and these functions make up to 60 per cent of warehouse operational costs. The demand today is for effective and flexible solutions and respond to changing business conditions, by adjusting capacity.

Trends

The supply chain is being impacted by a number of trends resulting both from the broader changes in society and advances in technology. Some of these are:

- Robotics that enhance inbound and outbound logistics for shippers

- Omnichannel logistics that facilitate smarter deliveries and address changing consumer habits

- The entrance of digital technologies (blockchain, drones, 3D printing, autonomous mobile robots, IoT connectivity, Big Data and VR amongst others)

- Customer-centric production and personalisation

“These are just a few examples. The future for intralogistics isn’t in a single technology like robotics, or sensors, or even Big Data, but rather how these elements can be tied together. Flexible robotics and data-driven solutions is the direction we see, with the end goals being cost-competitiveness for operations and a higher level of responsiveness and product availability for end customers,” continues Kaddoum.

E-commerce is another major trend to watch out for. Kaddoum says it is only going to grow larger in the coming years. “Traditional techniques of warehouse management are slowly becoming obsolete, and omnichannel orders mean your organisation needs to be ready with the right product on-hand, at the right time and ship it almost simultaneously with the customer’s ‘checkout’,” says Kaddoum. Keeping that in mind, some of the warehouse e-commerce best practices that Swisslog supports with their automated solutions are:

- Target Two-Day Shipping – Most major online retailers now offer their consumers the option of two-day delivery, if not same day shipping or pickup. Our solutions cater to this quick pace of business

- Combine Traditional and E-Commerce Warehouse Locations – E-commerce warehouses do not necessarily require a different location or warehouse. Many companies today house traditional retail, B2B and e-commerce warehousing operations under one roof. However, different sections of the facility may be used for specific e-commerce or traditional fulfilment purposes. The automated solution should be intelligent enough to work around this.

- Batch picking – The demand created by e-commerce requires quick and efficient picking of many different orders. Businesses recognise that best practices in picking mean fulfilling orders faster.

- Flexibility – A smart warehouse is one that is flexible. Operations should be adjustable and scalable depending on market conditions and demand. All plans and strategies need to adapt to real-time data regarding demand fluctuations, forecasts and changes in how consumers are ordering.

Trends that are impacting local retailers supply chains are:

- Artificial Intelligence and Robotics – While automated picking and packing have been around for a while now, the next wave of change is being brought about by artificial intelligence or AI. A warehouse that deploys robots reduces costs significantly while boosting efficiency.

- Focus on Supply Chain Visibility and Orchestration – Increasingly businesses in the Middle East are focussing on the better visibility of supply chains. This is only natural, given that the Middle East is a retail-strong economy. Greater visibility will mean an improved ability to orchestrate the supply chain for efficiency, service and lower costs.

- Smart Last Mile Fulfilment – Last mile fulfilment is always a big expense for companies. Therefore, there is a clear need to look for efficient and economic solutions. It is becoming increasingly popular in the Middle East to use telematics and route planning software to achieve smart last-mile fulfilment.

- 3D Printing – 3D printing is becoming increasingly popular in the Middle East. Customers with 3D printing capabilities only have to download patterns and create their own parts on site. The aerospace industry is an example of one such sector that has adopted this technique. If this trend continues, it is not an exaggeration to say that distribution centres may become printer farms in the future rather than the warehouses of today.

- Blockchain and Smart Contracts – Blockchain and smart contracts are very popular in the financial services industry. While it is still a relatively new concept in warehousing and logistics, the current trend indicates that this will be a way of life in the future. Blockchain enables “smart contracts“, which is the ideal solution for quality issues, late payments, delivery disputes etc. that are daily issues for logistics companies.

Solutions for local clients

For Mai Dubai, Swisslog is working on delivering a fully automated storage solution for two warehouses: one for raw materials and one for finished goods, standing 14m and 25m tall. Both warehouses are operated by pallet-stacking robots. Alongside the two facilities themselves, Swisslog has also delivered a 1km-long monorail system – the largest such system in the Middle East – that connects to and from the production area. The monorail uses 44 autonomous carts designed by Swisslog specifically for Mai Dubai. Each cart will carry two pallets. Overall, the project will more than double the current production capacity of Mai Dubai and will significantly increase its efficiency through the implementation of a fully automated storage and transport systems. Automation will also allow the racking systems to be packed closely together, allowing for greater storage density than with a manual warehouse. The project is scheduled to be delivered in the near future. The order value of the project amounts to UD$21 million.

Another brand that has been automated by Swisslog is Almarai in Saudi Arabia. The goal was to have processes run more quickly, increase transit quantities and reduce costs. To achieve this goal, Swisslog provided Almarai with several warehouses for palletised finished goods and a fully automated picking and goods distribution centre. Swisslog is also managing five sub-projects which implement the internal logistics systems within the various factories; step by step so that the company can continue to operate at the same time. The multi-million euro project included supply and installation of the following components: storage and retrieval machines, conveyors, refrigerated trucks (Automatic Reefer Loading System, ARLS), systems for automatic loading of HGVs, automatic picking modules supplied by KUKA, electric monorail suspension systems and SAP’s warehouse management system to control the material flows and data intelligently and efficiently.

Robots

“Robotic warehousing is no longer something out of science fiction,” says Kaddoum. “It is happening right now, and there are many advantages to this. The most obvious advantage is productivity goes up. Robots can work much longer hours and do not require as much rest. If deployed in shifts, robots can work 24/7, so your warehouse won’t ever need to close. They can also lift much heavier loads than human beings can. As a natural consequence of this, it means you won’t need as many pieces of heavy equipment – no more forklifts, for example, and the number of accidents in the warehouse will drop dramatically. Most of these robots have been designed with safety in mind and are programmed with a number of different safety routines to protect themselves, the products, and the people who work with them. On the same note, warehouses using robots require far less oxygen, which significantly reduces fire hazards. Space saving is another advantage of using robots. As robots are much smaller in size than forklifts, it means that the aisles between the shelves can be made narrower and this will improve the amount of space used to store things. With the space saving, more storage can either be added or rented out.”

A data-driven warehouse is one that effectively utilises operational software specifically designed for effective warehouse management. The advantages of this are many. Firstly, data can be used intelligently to analyse and optimise your warehouse, resulting in many critical insights. It also enables agility. With the help of data analysis, it is possible to future proof operations and stay flexible with IT solutions. Last but not least, intralogistics processes can be orchestrated to your needs, and you can keep your peak performance when needed.

Ecommerce and the retail supply chain

E-commerce has fundamentally changed the nature of the retail supply chain. Fast and accurate delivery of orders is critical to ensure customer satisfaction and make a profit. Some developments in robotics and automation technology in this sector are many.

Online shoppers require greater personalization. Therefore, warehouse managers must now consider automated solutions for split case picking, multiline item sorting and fast turnaround times. Further software should include functionalities such as returns handling, promotions and other value-add services.

The massive surge in e-commerce has prompted businesses to look for smarter and efficient ways to fulfil orders. Robots are the answer. In this sector, robots are now being used to assist with loading, unloading, sorting, picking, transportation, storage, delivery and audits. Robots helping with these tasks come in all shapes and sizes. They also use different forms of navigation tools such as rail, wire-guided, labels, magnet tape, laser, vision, geo-guidance and others. As time passes, robots will continue to become more intelligent and take over even more tasks than they currently do.

Use of robots has a number of advantages, all of which result in increased warehouse productivity.