CIMC Tianda: engineering the future of automated warehousing

CIMC Tianda Intralogistics is a powerhouse in intelligent logistics automation, offering cutting-edge solutions for warehouse and supply chain operations across the globe.

It forms a part of the larger CIMC Group, a major Chinese conglomerate with deep roots in industrial manufacturing and logistics. The company recently expanded in the Middle East with a strategic focus on automation in warehousing and logistics.

With more than 45 years of experience and over 1,800 global projects, its strong international foot print is noteworthy. In an exclusive interview with Aron Schiller, Director CIMC Tianda Intralogistics, Global Supply Chain uncover show seamless integration can be tailor made for almost every business model.

Gulf Supply Chain: In your opinion how do smarter logistics make the market more efficient?

Aron Schilller: Smarter logistics transform the market by enhancing visibility, transparency, and responsiveness across the entire supply chain. By integrating real-time tracking, predictive analytics, and automation, inefficiencies are minimised and decision-making is accelerated. This not only reduces costs and lead times but also enables businesses to adapt quickly to market fluctuations, ensuring products reach customers faster and more reliably.

GSC: CIMC Tianda Intralogistics is leveraging AI-driven logistics solutions to streamline storage, ensuring efficient international trade. Can you tell us more about this?

AS: Absolutely. At CIMC Tianda Intralogistics, we deploy advanced AI algorithms to analyse inventory patterns, forecast demand, and optimise storage allocation. Our “AI+WMS” system enables end-to-end warehouse automation through an “AIoT real-time perception + intelligent decision-making” framework. This includes dynamic path optimisation, intelligent task allocation, and real-time inventory alerts.

GSC: Can you share some of CIMC Tianda Intralogistics’s future industry trends?

AS: We foresee continued growth in automation, with robotics and AI becoming even more integrated into daily operations. Digital twins, virtual simulations, and advanced IoT sensors will provide unprecedented real-time insight into logistics networks. Sustainability initiatives—such as green warehousing and energy-efficient transport—will also become central, as the industry prioritises environmental responsibility alongside operational excellence.

GSC: What are some of the benefits of automated warehousing and intelligent tracking?

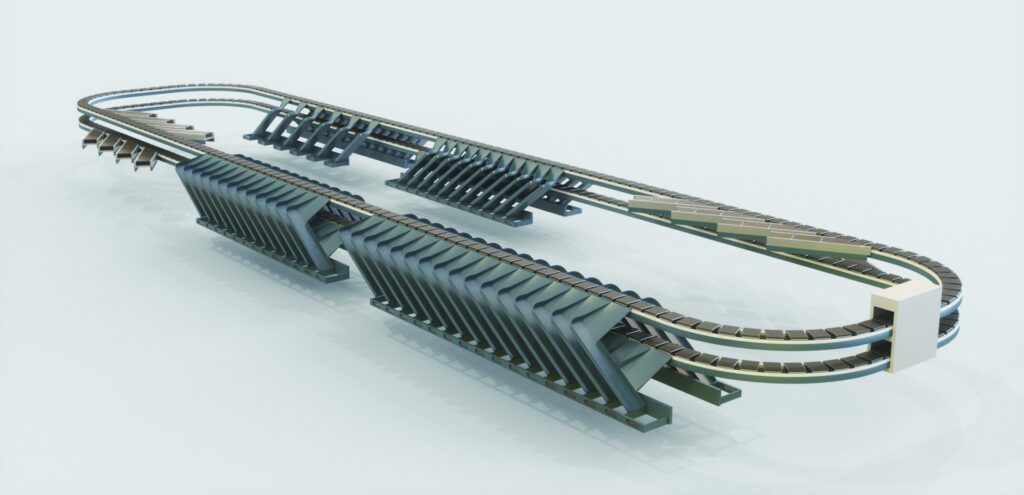

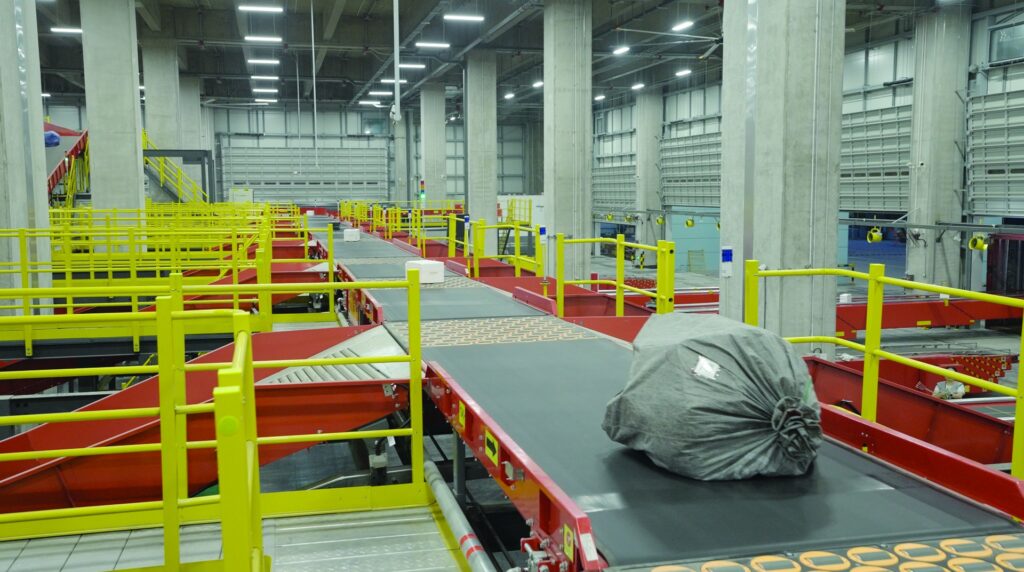

AS: Automated warehousing increases accuracy, reduces labour costs, and enhances safety by minimising manual handling. Intelligent tracking, powered by IoT and AI, offers end-to-end visibility, enabling proactive issue resolution, inventory optimisation, and improved customer satisfaction. Together, these technologies lead to faster turnaround times and a more resilient supply chain.

GSC: How does CIMC Tianda Intralogistics perceive optimising warehouses with the best automation?

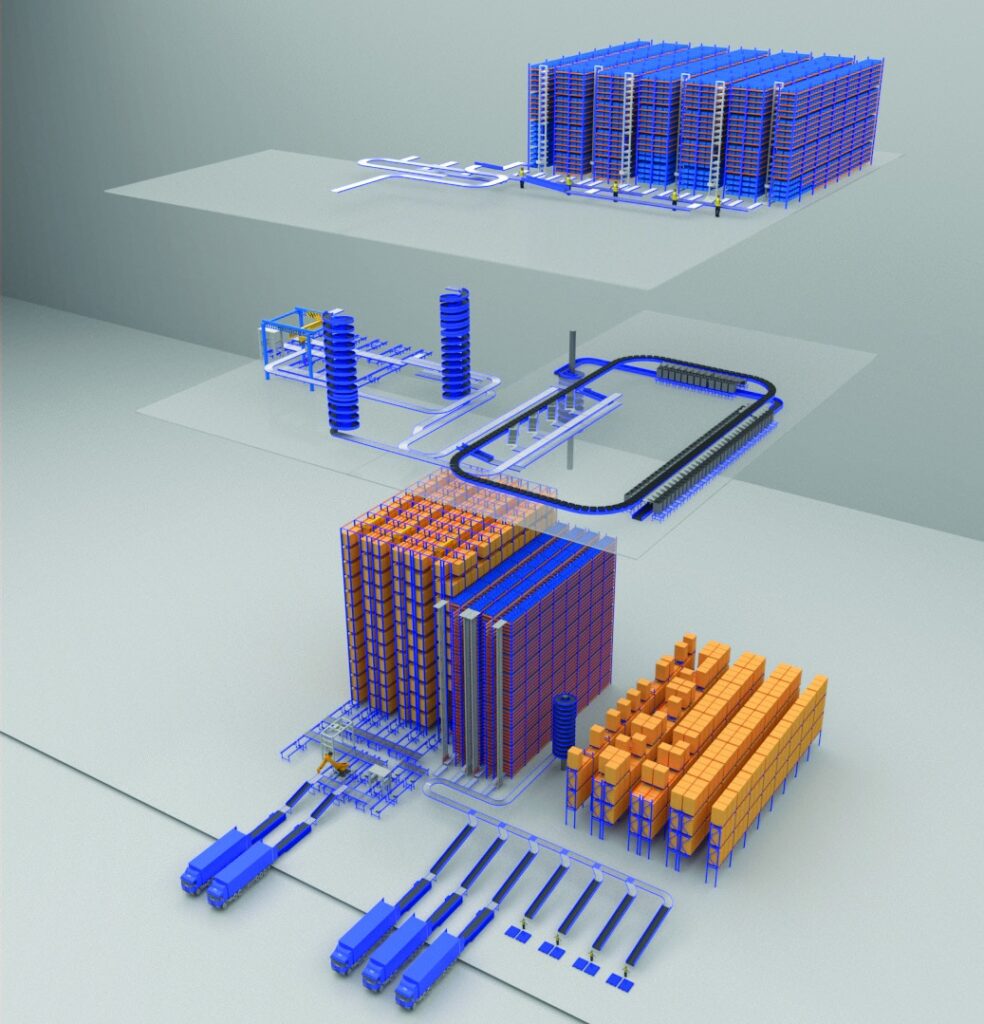

AS: We view warehouse automation and air cargo handling systems as a strategic imperative. By incorporating advanced robotics, automated storage and retrieval systems (AS/RS), and AI-powered management platforms, we create highly flexible and scalable environments. Our approach is tailored to each client’s unique requirements, ensuring optimal throughput, space utilisation, and cost efficiency.

GSC: How can CIMC Tianda Intralogistics help overcome the shortage of space for warehouses especially in the UAE?

AS: The UAE’s logistics sector faces spatial constraints due to rapid growth and regional growth of surrounding competitors in the logistics sector. We aim to address this by working hand-in-hand with our customers, designing high capacity and high performing automated solutions that maximise the logistic challenges faced in the country. Modular storage solutions and dynamic slotting algorithms ensure every square meter is used efficiently. Additionally, our systems enable faster goods turnover, reducing the need for excess inventory storage.

GSC: How does CIMC Tianda Intralogistics ensure seamless integration between AI and human workers in automated warehouses?

AS: We believe in a collaborative approach, where AI augments human capabilities rather than replacing them. Our systems are designed for intuitive human-machine interaction, offering user-friendly interfaces and real-time decision support. Comprehensive training and change management programs ensure our teams are empowered to leverage automation effectively, fostering a culture of continuous improvement.

GSC: What role does predictive analytics play in optimising warehouse operations?

AS: Predictive analytics is at the core of our operational strategy. By analysing historical and real-time data, we can anticipate demand fluctuations, identify maintenance needs, and prevent stockouts or overstocking. This proactive approach minimizes downtime, reduces operational costs, and ensures that resources are allocated where they’re needed most.

GSC: How is CIMC Tianda Intralogistics adapting warehouse automation for different industries (e.g., retail, pharmaceuticals, or heavy manufacturing)?

AS: Each industry has unique requirements. For retail, we focus on high-speed order fulfillment and returns management. In pharmaceuticals, our solutions prioritise traceability, regulatory compliance, and climate-controlled storage. For heavy manufacturing, we offer robust systems capable of handling large, heavy components. Our modular platforms allow for industry-specific customisation, ensuring optimal performance regardless of sector.

GSC: What strategies does CIMC Tianda Intralogistics use to manage data security in IoT-enabled warehouses?

AS: Data security is critical in warehouse management, especially in IoT-enabled environments.ClMC Tianda Intralogistics has developed a comprehensive security framework that protects warehouse data throughout its entire lifecycle, covering data access, transmission, storage, and device security.At the data access layer, role-based access control (RBAC) is fully implemented to restrict unauthorized operations. At the data transmission layer, communication channels are encrypted using protocols such as TLS/SSL and MQTT over TLS to prevent data interception. For data storage, AES encryption ensures data integrity and protection against tampering, while data minimization principles and anonymisation/desensitisation techniques are applied to protect sensitive information.

Additionally, at the device security level, a secure OTA firmware update mechanism is in place to automatically patch vulnerabilities and verify firmware integrity. Security modules are also embedded at the hardware level to defend against physical attacks.

More of this article can be found on https://globalsupplychainme.com/digital-issue-2025/sept-2025/